Thanks for signing up!

Join Our Newsletter

Receive the latest news on new promotions, exclusive offers, and new arrivals.

by test tester • April 15, 2025

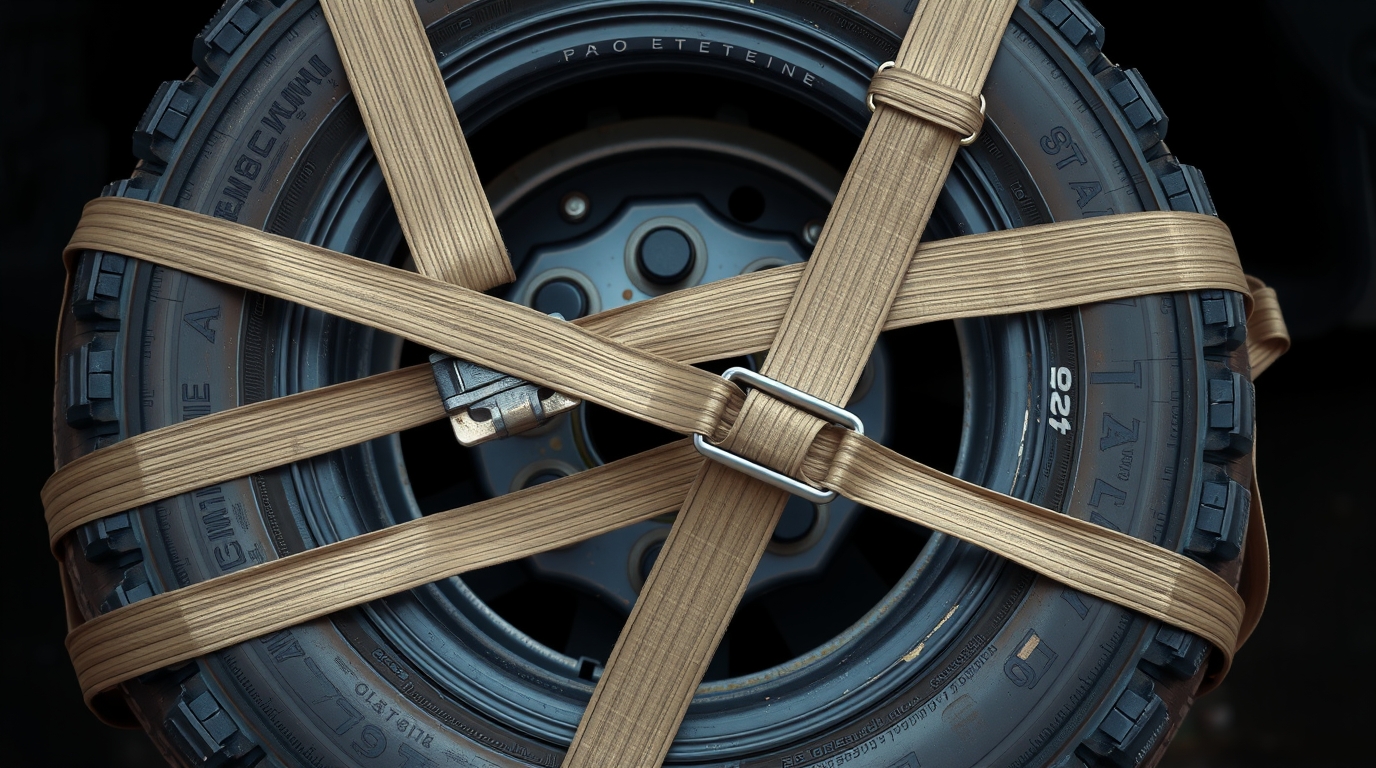

Transporting tires safely and efficiently is paramount, and that's where ratchet straps emerge as indispensable tools for any vehicle owner. Unlike ropes or chains, ratchet straps, often referred to as tire straps, deliver a secure and controlled tensioning mechanism, guaranteeing your precious cargo remains stable throughout the journey.

Choosing the correct type of ratchet straps and understanding their proper usage ensures both the safety of your tires and those sharing the road with you.

Ratchet straps provide a secure and reliable means of securing tires during transport, far superior to conventional ropes or bungee cords. These straps consist of a robust webbing material and a ratcheting mechanism, allowing for controlled tensioning and a tight, customized fit.

This adjustability is where the true value of ratchet straps shines, accommodating tires of varying sizes and ensuring your cargo remains stable throughout the journey.

By effectively limiting movement and preventing potential damage, ratchet straps offer unparalleled security for your tires, making them essential for any vehicle owner.

For detailed insights on tire-specific straps and best practices, check out Ultimate Guide: Tie Down Tire Straps for Safe Transport.

Delving into the mechanics, a ratchet strap for tires comprises mainly of a robust webbing strap, typically crafted from heavy-duty polyester webbing, and a ratcheting mechanism equipped with a release lever. This mechanism allows for effortless tensioning by simply cranking the ratchet handle, pulling the webbing taut around the tire.

A crucial aspect to consider is the strap’s working load limit, which reveals the maximum weight it can safely handle. Always opt for straps with a working load limit that exceeds the combined weight of your tires, guaranteeing safety and preventing mishaps during transit.

Furthermore, pay close attention to the types of hooks provided with the ratchet straps. Snap hooks, characterized by their spring-loaded closure, are a popular choice for tire tie-downs as they provide a secure connection point to anchor your straps to your vehicle or trailer.

Securing your cargo with the utmost care should be a top priority, especially when it comes to something as crucial as your tires. Choosing heavy-duty ratchet straps provides a sense of reassurance that your tires are held firmly in place, minimizing the risk of shifting or movement during transit.

Wheel tie-down straps, specifically designed for tires, often incorporate features like protective sleeves and durable hardware, ensuring your tires remain scratch-free throughout the journey. These straps, sometimes referred to as tie downs by seasoned haulers, offer a versatile solution, suitable for securing tires on trailers, trucks, or even in storage.

Moreover, investing in high-quality ratchet straps translates to a longer lifespan and enhanced safety, making them a worthwhile addition to your vehicle maintenance toolkit. Their ease of use, coupled with the superior level of security they offer, solidifies their place as a staple for transporting tires safely and efficiently.

Navigating the world of ratchet straps, specifically those designed for tire security, reveals a spectrum of options, each tailored to different needs and hauling scenarios. A key distinction lies in the type of end fittings, ranging from sturdy wire hooks and grab hooks, ideal for anchoring to D-rings and other tie-down points, to convenient snap hooks designed for quick and easy attachment to various anchor points on your trailer or truck bed.

Moreover, specialized wheel tie-down straps, equipped with rubber cradles or protective sleeves, provide an extra layer of protection against scratches and abrasions during transport. Understanding your specific hauling needs and the configuration of your vehicle or trailer will guide you towards the most appropriate type of ratchet straps, ultimately ensuring a safe and secure journey for your tires.

When investing in tire ratchet straps, prioritize quality and safety. Always check the strap's load limit, ensuring it surpasses the combined weight of your tires. Heavier-duty straps, while potentially costing slightly more, offer peace of mind and a longer lifespan, making them a worthwhile investment.

Examine the end fittings closely, too. Flat hook straps are a versatile choice for most haulers, while those with specialized hooks, designed to latch onto axle straps or specific anchor points, might be necessary depending on your vehicle and trailer setup.

Lastly, consider additional features that enhance ease of use and protection. Integrated protective sleeves help prevent scratches and abrasions on your tires, while soft loop tie-downs offer a gentler alternative for delicate wheel finishes. Remember, prioritize longevity and choose straps built with weather-resistant materials and corrosion-resistant hardware.

Before you begin, ensure that you have the appropriate ratchet straps, ideally heavy-duty wheel straps with a working load limit exceeding your tire weight. Clean your tires and the designated area on your trailer or truck bed to eliminate dirt, debris, or any substances that might hinder a secure grip.

Next, place your tires strategically, ensuring they're snug against any existing chocks or blocks on your hauling platform. This step minimizes movement during transit. Always consult your vehicle or trailer's manufacturer guidelines for recommended tire placement and securing procedures.

Before securing your tires, preparation is key. Begin by thoroughly cleaning your tires and the surface area on your car trailer or hauling platform where the tires will rest. This crucial step ensures optimal contact between the straps and the tire's surface, preventing any slippage during transit.

If you're using a trailer, ensure it's properly hitched and leveled. Engage the emergency brake for added stability during the securing process. For vehicles loaded onto a tow dolly, ensure the tires are centered within the dolly's wheel wells, and the safety chains are properly connected.

Regardless of your hauling configuration, always refer to your vehicle and trailer manufacturer's guidelines for specific instructions regarding tie-down points and recommended procedures. Employing the correct techniques ensures maximum safety during transit.

Begin by feeding the strap through the designated slots or around the tires, ensuring the ratchet mechanism is on the outside for easy access.

If your ratchet straps have swivel j hooks, carefully connect them to the appropriate anchor points on your trailer or truck bed, ensuring they are properly seated and secured.

Now, it's time to tighten the straps. Engage the ratchet by cranking the handle in a clockwise motion, pulling the webbing taut until you achieve a firm grip on the tire. Repeat this process for all tires, ensuring even tension across all straps.

Extending the life of your ratchet straps and ensuring their continued effectiveness in securing your valuable tires requires regular inspection and proper maintenance. Begin by examining the webbing for any signs of fraying, tears, or cuts. Remember, even minor abrasions can compromise the strap's strength and should be addressed promptly.

Additionally, check the ratchet mechanism for smooth operation and ensure the release lever functions correctly. Storing your ratchet straps properly when not in use, ideally in a clean and dry space, prevents premature wear and tear, guaranteeing their longevity and reliability for countless hauling trips.

Maintaining your ratchet straps is crucial for safe and successful hauling. Regularly inspecting your straps for wear and tear can prevent mishaps and ensure the longevity of this essential tool. Here’s a checklist to help you keep your straps in optimal condition:

If you encounter any damage, retire the strap immediately. It’s always best to err on the side of caution and replace a questionable strap than risk a potential failure during transport. Consider researching online for a series of videos showcasing proper ratchet strap inspection techniques and best practices for flatbed hauling, further enhancing your knowledge and promoting safe hauling practices.

Implementing proper safety practices when using ratchet straps, particularly those with wire hooks securing heavy loads, is paramount for accident prevention. Before each use, visually inspect your straps for any signs of damage, ensuring the webbing is free of cuts, fraying, or excessive wear.

Always double-check the working load limit (WLL) printed on the strap, confirming it exceeds the weight of the cargo you are securing. Overloading a strap can lead to catastrophic failure, potentially causing injury or property damage.

Furthermore, maintain a safe distance between your body and the tensioned straps while tightening. Always wear appropriate personal protective equipment, such as gloves and eye protection, when handling ratchet straps, guarding against potential injuries.

Ensuring your tires are properly secured with ratchet straps is crucial for safety on the road. Understanding the types and features of ratchet straps suitable for tires, as well as following a step-by-step guide for securement, enhances tire security during transport. Regular maintenance and safety checks are essential to uphold the integrity of the straps and prevent accidents.

By adhering to safety practices and storage guidelines, you can prolong the lifespan of your ratchet straps and ensure they are always ready for use. For more information or assistance, feel free to get in touch with us.

Even heavy-duty ratchet straps with high working load limits, typically constructed from durable polyester webbing, don't last forever. Replace them immediately if you notice any fraying, tears, or a decrease in load limit capacity. Regularly inspect them, especially after hauling heavy loads, to determine if replacement is necessary.

While heavy-duty ratchet straps, often crafted from robust polyester webbing, offer considerable resistance to various weather conditions, extreme temperatures or prolonged exposure to harsh elements can impact their strength and durability. If you frequently haul in challenging conditions, consider specialized weather-resistant tire straps for optimal performance and safety.

The maximum weight limit, commonly referred to as the working load limit, varies depending on the specific tire strap's design and construction. Always check the load limit (usually marked in lbs) printed on the strap's label before use. For safety, your chosen tire strap's working load limit should always exceed the combined weight of the tires being secured.

To extend the life of your heavy-duty ratchet straps, featuring durable polyester webbing and sturdy snap hooks, proper storage is crucial. After use, clean off dirt and debris, allow them to dry thoroughly, and store them in a cool, dry location. Avoid direct sunlight or exposure to extreme temperatures, as these can degrade the webbing over time.

Copyright © 2025 USA Ratchet